Can High Power Lasers Damage Fiber Networks?

High power lasers can destroy glass fiber if the fiber is not perfectly clean. This is called the “fiber fuse effect.” There isn’t too much written about this but it going to happen more frequently as optical networks evolve. The problem is more than just damaged fiber end faces. The effect also can kill the fiber up to a several meters distance from the connector or end-face.

A high-powered laser has 100 miliwatts of energy or more, 1/30th the glow of a night-light in a bedroom. While this is a tiny amount of energy in human terms, at the microscopic size of a fiber it is a very large amount of energy. A real world example is to think about a kid’s magnifying glass. If we put a piece of paper on the ground in direct sunlight, the paper will not ignite and catch fire. If we use the magnifying glass to focus the same sunshine light onto a concentrated spot on the paper, the paper will ignite. The glass lens concentrates the sun’s energy into a tight spot generating enormous heat. High powered lasers have the same effect on fiber cables.

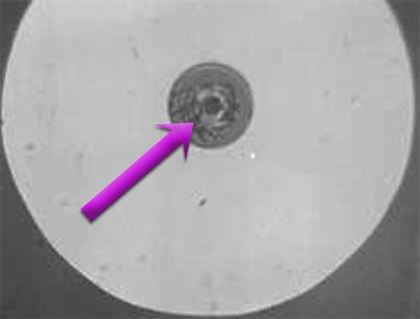

When the light from a high power laser contacts contamination on a fiber end-face, the light is stopped — it cannot pass through the contamination. Because of the 1st Law of Thermodynamics, we know the energy must go someplace. Trapped, it converts into a tremendous amount of heat in a small concentrated area. It gets so hot the contamination and glass transform into a plasma, fusing the contamination onto to the fiber core. These are the dark spots which can be seen with an inspection scope on the fiber.

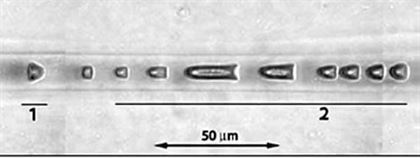

Surprisingly, the optical energy also can flow backwards into the fiber from which it came. This not only alters the fiber cladding’s properties but could also damage the transmitting components like the laser and amplifiers on the line. The photo below shows the damage that can occur.

This image shows damage from contamination which was not removed prior to the fiber being irradiated with a 100mW laser. The damage reflected backwards from the contamination and melted little “bubbles” in the fiber. The bottom image shows the holes in the fiber caused by the plasma. Images courtesy the Photonics Group at the Imperial College of London

An equipment maker like Cisco uses sophisticated engineering to determine the power of the required light source on a given fiber link. The factors involved vary widely based on many “stackable” factors like fiber type, transmission distance, signal type, equipment in the line (i.e. Raman amplifiers or EDFA), the power budget, etc. Regardless of the equipment and the power, there is one universal theme: All networks need to have a contaminant-free path for the signal to pass through. Clean AND inspect every end-face, both sides, every time you mate them together with enginnered fiber optic end face cleaners and tools.

This image shows damage on a fiber end-face from contamination which was not removed before the connector was irradiated with a 100mW laser. The contamination absorbed the light, converted it into heat, and fused the central contact area of the fiber. Image courtesy NTT AT of Japan.