Is a Bi-Solvent Cleaning System a Good Option for Critical Cleaning?

In the world of vapor degreasing, there are three types of solvent degreasing systems: mono-solvent cleaning, co-solvent cleaning and bi-solvent cleaning. Here we take a deep dive into the bi-solvent cleaning process:

In general, the MicroCare mono-solvent cleaning fluids can perform all of the required cleaning jobs. But once in a while a customer has a particular contamination that can’t be managed by a single solvent cleaning process. This can happen because of specific types of contaminants, materials compatibility issues, throughput issues or maybe environmental regulations.

A co-solvent cleaning fluid system might fix the problem by adding a strong, non-volatile solvating agent to the boil sump of the degreaser. But this can be limited by the temperature of the rinsing fluid. If the rinsing fluid boils at 40˚C, and the contamination needs to reach 100˚C to be cleaned, no amount of co-solvent scrubbing is going to get the job done.

Therefore, once in a great while, customers need a second machine which operates at much higher temperatures. This will deliver approximately the same convenience and speed of traditional mono-solvent cleaning, but amplified by the second solvent and much higher temperatures. This bi-solvent process provides the additional muscle or horsepower that the application requires.

How Does It Work?

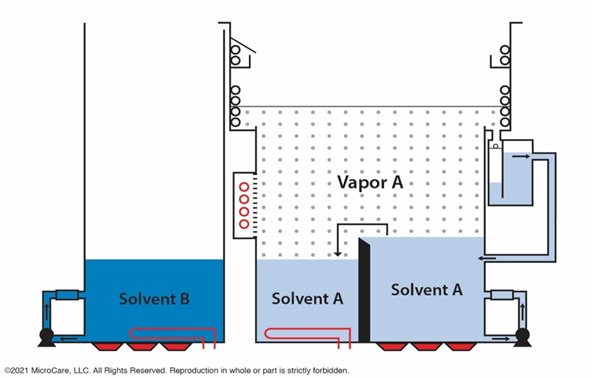

The two solvents have very different behaviors. The solvating agent of the bi-solvent cleaning system (Solvent B) is located outside the degreaser in a separate cleaning tank. It operates at much higher temperatures than the rinse agent.

The rinse agent (Solvent A) inside the vapor degreaser (typically an HFC, HFE or HFO based rinsing agent) boils at a lower temperature (like the MicroCare™ and Vertrel™ solvents). They both rinse the bi-solvent from the parts and also rinse any lifted or loosened contamination from the parts.

The bisolvent fluid is collected in the distillation phase of the rinse degreaser and usually can be recycled and re-used, which saves money.

The bi-solvent system delivers excellent cleaning on all types of solder fluxes, oils, greases, waxes, and particulates, paints, buffing compounds and anti-rust agents. It is highly compatible with most metals and ceramics. It also has broad compatibility with plastics and elastomers that can withstand the boiling temperatures. Bi-solvent cleaning delivers excellent cleaning without water or other problematic cleaning products.

In summary, a bi-solvent cleaning system should be used only for the most difficult soils, which often require high temperatures for removal. In the right application they can provide superior cleaning results without the throughput delays inherent in aqueous systems.