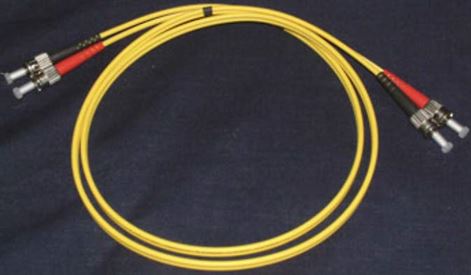

Should I Clean Patch Cables — Especially New Ones Right Out of the Bag?

Everybody asks, how to clean patch cables, also called patch cords or jumpers. But what they really are asking is, do I need to clean them, when they’re new and right out of the bag? The answer is yes, you do. Here’s why:

There are three “P”s to perfect fiber connectivity:

- Perfect core alignment

- Perfect physical contact (no air gaps between end-faces)

- Perfectly pristine connector end-faces and interfaces

The only variable techs easily can control is the cleanliness of the end-face. More than 33% of all new patch cords are sufficiently contaminated as to degrade the network. This is true even when the patch cords are coming right out of the bag, even when the dust caps are still in place. Overall, “75% of network troubleshooting is the result of optical fiber connectors that are dirty or damaged by dirt,” according to Matt Brown, “Inspect Before You Connect,” BICSI News, Nov 2008.

The Sticklers™ team strongly suggests that techs clean and inspect every jumper cable and patch cord before mating them into panels and systems. This especially applies to brand new jumpers and patch cords, right out of the bag.

Clean and inspect every patch cord and jumper cable, both ends, every time you mate them

The Economics of Patch Cables

How can this be? Well, patch cords are a commodity, so the primary distinction between brands is the price. This drives all the makers to get their price as low as possible. That means they have to get their costs down, too. Cleaning is an extra step that can be avoided — after all, the customer is going to clean the connectors before mating! — so most simply don’t bother to clean.

Even if they do clean the end-faces, they don’t clean the end-caps and they certainly don’t clean the plastic shipping bags. Never assume that a new cable assembly is clean. End-caps usually are made with PVC plastic softened with plasticizers. These chemicals can leach out from the PVC and transfer to the connector end-face. “Out-gassing” is a major concern if the assembly is exposed to high temperatures, such as being in a sealed shipping container crossing the Pacific Ocean.

To keep repair costs low, customer satisfaction high and networks fast, it makes sense to clean every patch cord connection, every time, with engineered fiber cleaning fluids and tools before mating.