The Meaning of Kb Value in PCB Cleaning

The cleaning strength of a PCB cleaner is frequently measured using an industry benchmark called the Kauri Butanol (Kb) value. A higher Kb value is usually better and means the cleaner is more aggressive. But there are trade-offs. For instance, stronger solvents can have compatibility problems with plastics, coatings, inks and other components. So, smart engineers should examine the Kb value of their cleaning products to avoid expensive surprises.

Effective Cleaning

Contamination-related failure within the electronics industry is growing. Since smaller, more densely-populated circuit boards are becoming the norm, the issue of managing faults and guaranteeing the quality of the devices is important. Therefore, an effective cleaning process is critical to the longevity of electrical components. But it can be highly challenging. Many manufacturers are opting for solvent cleaning because they find it more effective, flexible and less expensive than other methods like aqueous cleaning. But before deciding which solvent to use, it is important that they study their Kb values. They are a good benchmark and starting point for analysis.

The Kb Test

The cleaning strength of solvent cleaners is calculated by the Kari-Butanol (Kb) test. It is a standardized test endorsed by the International Association for Testing Materials (ASTM). Kb testing is a simple process that uses a standardized test material called butanol – a thick, rubbery gum. This is immersed in the solvent for a set time under controlled conditions (temperature, pressure, etc.). Then the remaining butanol is measured to determine the quantity of material dissolved by the solvent. A value of 10 is very mild while anything over 70 is an aggressive solvent. This index is used to judge the relative cleaning power of cleaning fluids and is useful when choosing a solution for use on PCBs.

Kb values are found on the cleaning fluid’s technical data sheet. These figures help you gauge the cleaner’s strength and suitability for the contaminant to be removed. For instance, cleaning fluids with lower Kb values will dissolve greases but may not handle ionics and fluxes. Cleaning fluids with higher Kb values may be speedy and effective cleaners but may attack delicate plastic components. For this reason, it is important to consider the components to be cleaned and the materials they house.

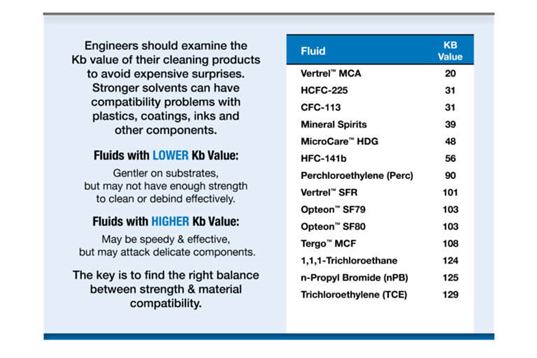

Dependent on the contamination, make sure the cleaning fluid has the “horsepower” to dissolve the contamination and clean it effectively without affecting the component itself. Kb values help gauge a fluid’s cleaning strength. Fluids with lower Kb values are gentler on substrates but may not have enough strength to clean effectively. Fluids with higher Kb values may be speedy and effective but may attack delicate components. The key is to find the right balance between strength and materials compatibility.

Kb Values Compared

Other Factors to Consider

Although Kb values are a good indicator of the cleaning fluid’s strength, there are other factors to consider. The Kb test itself has some limitations. For example, it must be performed at 25°C (77°F) and within one atmosphere pressure. Testing under other conditions yields different results. In addition, there are some cleaning fluids that cannot be evaluated using the Kb method since they dissolve the butanol gum almost instantly. Therefore, it is important to use cleaning fluids from a trusted source to ensure testing has been done under standardized and regulated conditions.

Selecting a cleaner with optimal Kb value is a balancing act. There are a number of factors affecting cleaning performance. Technicians must also consider surface tension and density, toxicity, flammability, and the cost-per-part-cleaned. There are also environmental and safety implications and regulations imposed on cleaning fluids. The choice needs to be sustainable for the future without compromising the cleaning performance needed today.

Test Before Use

Many engineers today will not only look at the Kb values but will also rigorously test cleaning fluids on their components, contamination and cleaning processes to mimic real-world conditions. It is difficult to predict the cleaning effectiveness of a fluid without tests. For instance, the results of a cleaning process can vary by contamination, selected cleaning fluid, application, cleaning system and physical shape of the parts being cleaned. Therefore, it is important to simulate the actual cleaning conditions as closely as possible.

Reliable cleaning fluid suppliers offer with testing by conducting cleaning trials. Tests will be undertaken to select the correct cleaning fluid for the component and the contamination. Results are analyzed to select the correct critical cleaning fluid and process required, weighing all the elements to find the perfect cleaning solution for the job.

Often the results are unexpected. Some mild cleaning fluids may clean as well or even better than those with much higher Kb values while maintaining excellent materials compatibility. Importantly, cleaning fluids can be custom-tailored to have a wide range of Kb values, leading to a very versatile cleaning performance.

So, when considering the Kb value, remember to look at the whole picture and seek professional advice for your specific critical cleaning requirements. PCB cleaning experts can suggest the cleaning fluids and processes that will work best for each application.

Special Note: The benchmark resin actually is the sap from the kauri tree (Agathis Australis) that only grows in New Zealand. Chemists searched for a solvent to liquefy that resin to make it useful industrially. They found that the gum was easily dissolved in butyl alcohol, so that became the benchmark solvent and is the source of the name of the test, the Kauri-Butanol test.