How Easy is it to Convert to a Bi-solvent Cleaning Process?

Bi-solvent cleaning using a vapor degreaser delivers the convenience and speed of traditional mono-solvent solvent cleaning, but intensifies this cleaning with a second cleaning fluid. This second high boiling point, non-volatile solvating agent provides the additional cleaning muscle needed to remove very tenacious soils like heavy greases and thick waxes.

Most fabricators turn to bi-solvent cleaning inside their vapor degreasers if they are having trouble getting parts clean using a mono-solvent or co-solvent cleaning process. Common problems include:

- Poor cleaning results on extra tenacious soils

- Compatibility issues with either the substrate or the contaminant or soil

- Toxicity concerns of the current cleaner

- Regulatory changes or scrutiny of the existing cleaner

Few Equipment Changes Needed

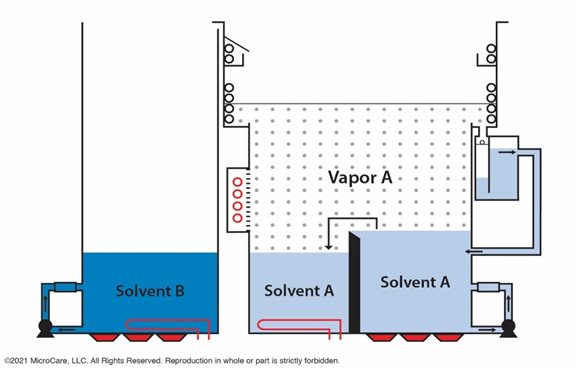

An additional tank with heat, and possibly ultrasonics, will be required to contain the bi-solvent solvating agent (Solvent B). This tank will be placed next to the vapor degreaser prior to the boil sump.

Other simple modifications maybe necessary depending on present heating and cooling capacities as well as cleanliness requirements. These include things like resetting temperature controls or adding a still to improve heating and cooling capacity. No additional venting is needed.

No Maintenance Required

The bi-solvents inside the vapor degreaser require little monitoring and do not need acid acceptance testing or boosters unlike legacy solvents including nPB. The vapor degreaser uses and recycles the bi-solvents for hundreds of hours before they need to be replaced. The vapor degreasing system concentrates the soils which are periodically removed and disposed, saving on hazardous waste costs.

Other Costs and Savings

Bi-solvent cleaning is typically more complicated than mono-solvent or co-solvent cleaning due to the secondary cleaning tank. However, bi-solvent cleaning does reduce the time and labor costs trying to unsuccessfully re-clean dirty parts.

Easy Operations

In most instances, operating parameters are similar to mono-solvent and co-solvent cleaning processes. The cleaning cycle could be slightly longer. The specifics can easily be determined through a cleaning trial conducted inside the MicroCare Critical Cleaning Lab. Send us your soiled parts and we can determine which cleaning solvent(s) and methods are right for you.