Is Co-Solvent Cleaning in a Vapor Degreaser a Good Option?

Most companies do not need the extra cleaning horsepower provided by co-solvent cleaning systems. However, for special applications it is a very smart and sophisticated option.

In general, the MicroCare monosolvent fluids can perform all of the required cleaning jobs. The problem arises when you can’t get the cleaning horsepower you need from a monosolvent system. This can happen because of contamination types, materials compatibility issues, throughput issues or maybe environmental regulations. In this case, you are going to need to add some cleaning power.

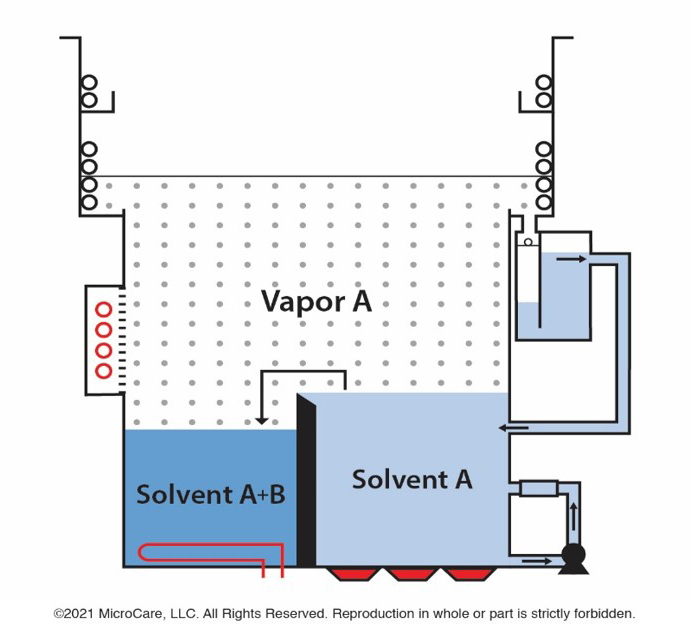

A co-solvent system delivers the convenience and speed of traditional monosolvent cleaning, but amplifies this cleaning with a second component or set of components. This second portion (Solvent B) provides the additional muscle or horsepower that the application requires.

The two solvents have very different and distinct behaviors. The primary difference between the two solvents will be their boiling points: one boils at a low temperature (Solvent A) and the other (Solvent B) boils at a much higher temperature. They work together to supplement, enhance or boost overall cleaning performance.

The low-boiling solvent (Solvent A) is referred to as the rinsing agent and is formulated based on HFC, HFE or HFO fluids. The rinsing agent washes the solvating agent (Solvent B) off the components and provides the vapor blanket for the system.

The Tergo™ Chlorine-Free Cleaning Fluid is the MicroCare co-solvent cleaning product, engineered for maximum environmental protection. It is a two-part, nonflammable, non-chlorinated, multi-functional cleaning fluid engineered for use in vapor degreasers and is referred to as a “co-solvent system.” The solvating additive is a proprietary, non-volatile, high-boiling point mixture. The rinsing agent is a low-boiling hydrofluoroethers-based (HFE) solvent blend. Together, the system delivers excellent cleaning on all types of solder fluxes, oils, greases, waxes, and particulates, paints, buffing compounds and anti-rust agents. It is highly compatible with most metals, plastics and ceramics; it also has and broad compatibility with plastics and elastomers.

Many co-solvents may be able to be used inside existing two-sump vapor degreasers, however, it’s best to consult with one of our MicroCare applications specialists to determine if this will be the case in your particular application.

In summary, a co-solvent system should be used only for difficult soils, which often require high temperatures for removal. In the right application they can provide superior cleaning results without the throughput delays inherent in aqueous systems.