Universal Electrical Contact Cleaner (3M Novec Contact Cleaner & Contact Cleaner Plus Replacement)

Product Information

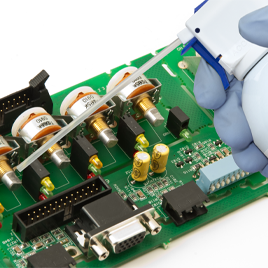

The Universal Electrical Contact Cleaner removes soils from hard-to-reach places

Applications:

- Rinses and flushes contamination away

- Unlike flux removers, it does not dissolve the contaminants

- Restores electrical continuity

- Cleans dust, grit and dirt as well as mineral oils, silicone oils, hydrocarbon based oils and fluorinated oils/grease

- Rinses grit from hot motors, dust from inside electromechanical relays, keyboards and other electrical devices

- Use on connectors, switches, cable harnesses, tuners, power supplies, encoders, distribution panels, junction boxes, coax cables, and windings

- Excellent replacement for 3M Novec™ Contact Cleaner and Novec Contact Cleaner Plus

Features:

- No residue / no rinsing

- Mild cleaner is non-corrosive and safe on most plastics, rubber and elastomers

- Kb Value: 34 (est.)

- Fast drying for speedy cleaning

- Chemical Family: HFO

- Nonflammable for maximum safety

- VOC Content (g/L): 59, VOC exempt

- RoHS/WEEE/REACH/EPA SNAP compliant

- Formulated in USA

Universal Electrical Contact Cleaner is sustainable with a very low global warming potential (GWP) of 1. The aerosol cans are both TriggerGrip™ Cleaning Tool compatible and StatZAP™ ESD Eliminator Tool compatible.

Product Details

Product Image |

Part Number | Package | Weight | Size | Technical Data Sheet | Safety Data Sheet |

|---|---|---|---|---|---|---|

|

CCH10A ES8300 1622 1632 ES7300 ES1612 ES1677 ES1605 ES1629 ES1613 401B 409B CCH10A | Aerosol | 0.3 kg 0.66 lb. | 310 ml 10.5 oz. |

| Part Number | CCH10A |

|---|---|

| Package | Aerosol |

| Weight | 0.3 kg 0.66 lb. |

| Size | 310 ml 10.5 oz. |

| Technical Data Sheet | |

| Safety Data Sheet |

Scroll

| Odor | Slight |

|---|---|

| Boiling Point | 19ºC / 66ºF |

| Chemical Family | HFO Solvents |

| F-Gas Compliant | |

| Evaporation Rate | Fast |

| Cleaning Strength (Kb) | 34 |

| Flashpoint | None |

| Global Warming Rating (100yr) | 1 |

| VOC Organic Content (g/L) | 59 |

| Ozone Impact | Zero |

| REACH & ELINCS Compliant | |

| RoHS & WEEE Compliant | |

| Safety Rating | Non-flammable |

| Specific Gravity | 1.24 |

| Viscosity | n/a |

| Vapor Pressure @ 20ºC | 1.91 |

- MicroCare Lab Services for Critical Cleaning

- Mike’s Radio Repair Demonstrates the TriggerGrip™ Cleaning System

- Azeotropes Explained

- Our Chemistries and Expertise Set Us Apart - APEX 2020 Interview

- Solder Paste and Flux Cleaning Results Revealed

- Cost-Cutter: Seven Ways to Save Money Cleaning PCBs

- How-to Connect and Disconnect the TriggerGrip Cleaning Tool

- How-to: Using the TriggerGrip PCB Cleaning Tool

- Best Practices: Cleaning During PCB Rework and Repair

- MicroCare Partners in RENEX Hand Soldering Championship 2019

- Static Dissipative Wipes Clean Without Worry

- Cost Saving Products for Benchtop Cleaning

- Case Study #15 — Cleaning Mixed Flux Residues from PCBs

- Going Green with Vapor Degreasing

- MicroCare Leads the Way on Worker Safety and Regulatory Compliance

- MicroCare Critical Cleaning Experts

- The MicroCare Reliable Care Way

- Ensure Contact Cleaner Compatibility with Today’s Complex Electronics

- TriggerGrip InfoGraphic

- 4 Types of PCB Contamination and How to Remove Them

- An Early PCB Cleaning Plan Leads to Manufacturing Success

- Cleaning and Drying Before Conformal Coating: Why It’s Important

- MicroCare Offers IPA Alternative Cleaners

- Modern Electronics Require Updated Cleaning Methods

- Modern PCBA Cleaning: Methods to Improve Reliability

- Removing PCB Conformal Coatings

- Use Toxicity Ratings to Help Ensure Worker Safety

- The Meaning of Kb Value in PCB Cleaning

- Why Clean a No Clean Flux

- Flux Remover Selection Guide

- The Importance of Drying in PCB Cleaning

- All Electronics Cleaning Wipes Are Not Created Equal

- Safer Cleaning Choices Replace nPB in Aerosols for Worker Safety

- Circuit Board Design & Cleaning Evolves to Support Down-Hole Logging Technologies

- Stencil Wiping Fabric Improves Stencil Printer Through-Put